Was ist Asphalt?

Asphalt ist ein Baustoff, der aus einem Gemisch von Bindemittel (Bitumen), Gesteinskörnung und Füller (feiner Sand) besteht. Asphalt kann technisch hergestellt werden, findet sich jedoch auch in natürlicher Form und wird unter anderem in Trinidad, Venezuela, Schweiz, Kalifornien, Syrien oder auch in Deutschland abgebaut. Der Naturasphalt, oder auch Erdpech genannt, wird derzeit ausschließlich im niedersächsischen Holzen durch Untertagebau abgebaut.

Was sind die Eigenschaften von Asphalt?

Asphalt verhält sich chemisch nahezu inert (träges Reaktionsverhalten) und weist ein thermoplastisches Verhalten auf.

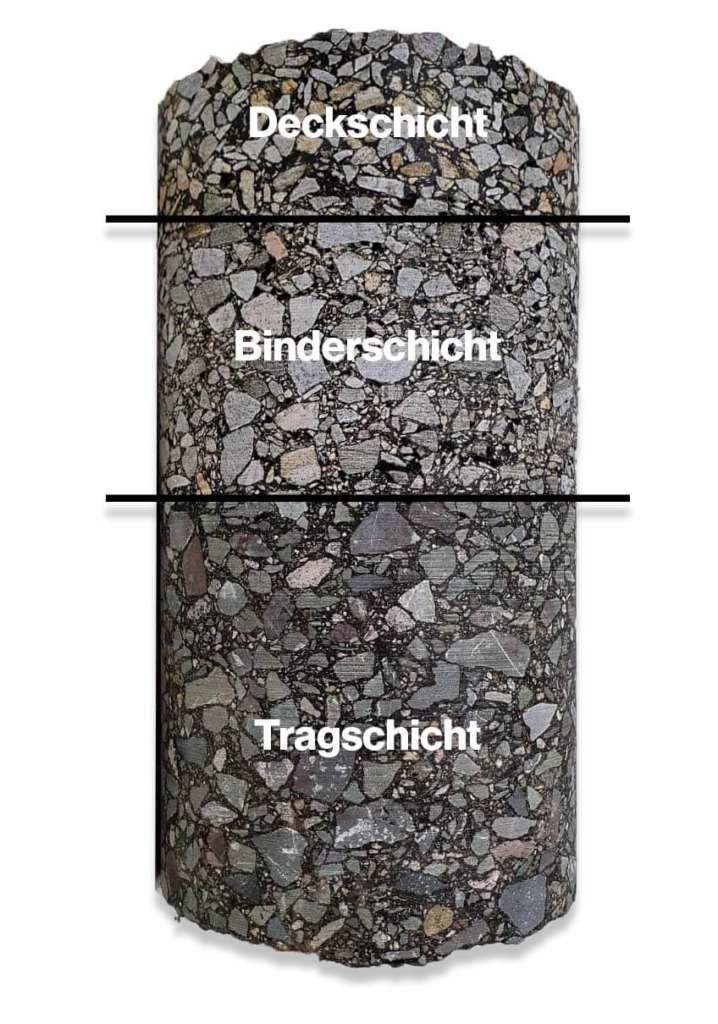

Im Straßenbau besteht Asphalt aus drei Schichten, welche durch ihre Dicke und Lage die Tragfähigkeit der Straße bestimmen. Sie müssen zu einem kompakten Baukörper verbunden sein.

Wo wird Asphalt eingesetzt?

Die Asphalt Performance ergibt sich aus den Eigenschaften des Baustoffs. So findet dieser in folgenden Bereichen Anwendung:

- Straßenbau für Fahrbahnbefestigungen, bzw. Straßenbelag

- im Hochbau für Fußbodenbeläge

- im Wasserbau zur Abdichtung

- im Deponiebau zur Abdichtung

- in Garten- und Landschaftsarchitektur (mit farbigem Asphalt) zur Gestaltung von Wegen, Plätzen und Freizeitanlagen

Jedoch kann nicht jedes Asphaltrezept in einer beliebigen Schicht oder universell für unterschiedliche Anwendungen eingesetzt werden. Sehr grobkörniges Mischgut sollten dicker, sehr feinkörnige Mischgutsorten können dünner eingebaut werden.

Welche Asphaltschichten gibt es und was sind ihre Funktionen?

Straßen bestehen aus drei Schichten: Der Trag-, Binder- und Deckschicht. Die Asphalttragschicht ist die unterste Schicht, welche aus Bitumen, Füller und einem Gesteinskörnungsgemisch besteht. Die zweite Schicht ist die Binderschicht. Den Abschluss macht die Deckschicht, welche für den Autofahrer sichtbar ist.

Asphaltschichten schützen das Fundament und den Untergrund vor Niederschlägen, um die Tragfähigkeit der Gesamtkonstruktion zu erhalten. Der feste Verbund von Asphaltschichten trägt die Verkehrslast ab und verteilt diese auf die Unterlage. Durch diese Systematik nimmt die gesamte Straßenbefestigung keinen Schaden.

Tragschicht:

Die zusätzlichen Technischen Vertragsbedingungen und Richtlinien für Tragschichten im Strassenbau (ZTV T-StB) sehen eine Mindestdicke von 8 cm vor. Weitere Regelungen zur Asphalttragschicht sind in den Richtlinien für die Standardisierung des Oberbaues von Verkehrsflächen (RStO)“ festgelegt.

Wird auch als Asphaltbinderschicht bezeichnet. Binderschichten kommen bei stärker belasteten Straßen, ab der Bauklasse 3 zum Einsatz. Die Binderschicht bildet den Übergang zwischen der grobkörnigen Tragschicht und feinkörnigen Deckschicht. Hierdurch ebnet sie die Oberfläche der Tragschicht, sodass eine plane Deckschicht aufgetragen werden kann. Durch diese Ebenheit ist es der Straße möglich die hohe Schubspannung des Verkehrs aufzunehmen und Verformungen zu verhindern. Die RStO empfehlen je nach Bauklasse eine Schichtdicke von 4 bis 8 cm.

Die Zusammensetzung der Asphaltbinder regeln die „Zusätzlichen Technischen Vertragsbedingungen und Richtlinien für den Bau von Fahrbahndecken aus Asphalt“ ZTV Asphalt-StB.

Ist die oberste, direkt beanspruchte Schichten der Asphaltbefestigungen und sollte 4 cm dick sein. Sie unterliegt den unmittelbaren Einwirkungen des Verkehrs, der Witterung und der Auftaumittel. Die Schichtdicke ist in der ZTV Asphalt-StB und RStO geregelt. Die Asphaltdeckschicht ist explizit für die Abnutzung durch den täglichen Verkehr konzipiert. Im Rahmen eines regelmäßigen Deckenbauprogramms ist diese Schicht jedoch zu erneuern.

Welche Asphaltsorten gibt es?

Der Unterschied der verschiedenen Mischgutarten liegt in der Zusammensetzung der Gesteinskörnung und dem Bindemittelgehalt. Hinsichtlich der Einbauverfahren ist zwischen Walzasphalt und Gussasphalt zu unterscheiden. So muss Walzasphalt immer durch Straßenwalzen verdichtet werden, hingegen Gussasphalt im flüssigen Zustand verarbeitet wird und eine Verdichtung entfällt. Die Wahl der Mischgutsorte richtet sich nach der Verkehrsbelastung und der gewünschten Oberflächenstruktur (fein- bis grobrau).

- Asphaltbeton (Heißeinbau): Gehört zu der Deckschicht und ist für Straßen der Bauklassen 2 bis 6 und Wege aller Art geeignet. Asphaltbeton zeichnet sich durch seine hohlraumarme Zusammensetzung aus und besteht aus Edelsplitt, Edelbrechsand, Natursand, Füller und Bitumen. Der Einbau erfolgt bei ca. 120°C. Seine Rauheit erhält Asphaltbeton durch Splitt, welcher auf die heiße Deckschicht gestreut und mit der Walze eingearbeitet wird.

- Asphaltbeton (Warmeinbau): Gehört zu den Deckschichten uns ist für Verkehrsflächen mit geringer Belastung der Bauklassen IV bis VI geeignet. Er wird bei ca. 60°C eingebaut und erhält seine endgültige Dichtigkeit erst durch die Verkehrsbelastung. Der Baustoff besteht aus einem Mineralgemisch und Fluxbitumen. Aufgrund des Umweltschutzes und des Fluxbitumens findet der Warmeinbau kaum noch Anwendung.

- Splittmastixasphalt: Spezielle Sorte für Deckschichten mit einem höheren Bitumen- und Splittgehalt. Zusätzlich besteht er aus Straßenbitumen oder polymermodifiziertes Bitumen (PmB) und stabilisierenden Zusätzen (z. B. Zellulose- oder synthetische Fasern). Die Modifikation soll die Haltbarkeit erhöhen, weshalb Splittmastixasphalt für hohe Verkehrsbelastung (z.B. auf Autobahnen) geeignet ist.

- Gussasphalt: Besitzt einen hohen Anteil von Bitumen und Füller, wodurch eine optisch glatte Oberfläche entsteht. Die Hohlräume des Gesteinskörnungsgemisches sind vollständig mit Bitumen ausgefüllt. Dadurch ist er flüssig verarbeitbar. Die Einsatzgebiete sind hoch beanspruchter Straßen (Autobahnen) und Brücken durch die hohe Wasserdichtigkeit. Damit die Griffigkeit gewährleistet bleibt, wird beim Einbau des Asphalts feinkörniger Splitt aufgestreut und eingewalzt.

- Asphaltmastix: Weist einen geringen Bitumenanteil auf und dient überwiegend zur Abdichtung von Bauwerken und zum Verfüllen von Fugen. Daher wird Asphaltmastix im Straßenbau tendenziell für Reparaturen, Ausbesserungen oder zur Oberflächenverbesserung eingesetzt.

- Asphalttragdeckschichten: Kombiniert die Funktionen von Asphaltbeton und Asphalttragschicht in einem. Dieser Asphalt kommt häufig im landwirtschaftlichen Wegebau vor, da eher verhältnismäßig preiswert ist.

- Offenporige Asphalte: OpA oder auch Flüsterasphalt genannt, ist eine spezielle Form der Asphaltdeckschicht, die aus verhältnismäßig großen Körnern besteht und dadurch eine poröse Struktur aufweist. Durch seine besondere Struktur absorbiert der Asphalt Geräusche. Auf Autobahnen und Schnellstraßen ist er etabliert.

- Niedrigtemperaturasphalt (NTA): Niedrigtemperaturasphalt ist normaler Asphalt, der mit einem anderen Prozess hergestellt wird. Diese verschiedenen Herstellungsmethoden führen dazu, dass weniger Energie beim Einbau benötigt wird. Schnelleres Auskühlen, schnellere Verkehrsfreigabe und schnelleres Durchführen einer Erhaltungsmaßnahme sind die Folge.

Warum gibt es Asphaltprüftechnik?

Straßen verbinden nicht nur Städte, sondern auch Menschen. Sie überziehen unseren gesamten Planten und bestehen hauptsächlich aus Asphalt. Dieser Baustoff unterliegt je nach Verwendungszweck (z.B. Straßenbau, Flugbetriebsflächen oder Rad-/Fußwege) unterschiedlichen Anforderungen und gesetzlichen Normen. Um sicherzustellen, dass Qualitätsvorgaben eingehalten werden, sind Materialprüfungen durchzuführen.

So setzten beispielsweise Asphaltmischanlagen die Asphaltextraktion zur Selbstkontrolle ein, um ein Mischgut entsprechend des Asphaltrezeptes zu gewährleiten. Im Weiteren ist eine Fremdüberwachung durch Institute notwendig, die wiederum die Erzeugnisse der Asphaltmischanlagen kontrollieren.

Ergänzend gewinnen die Themen Recycling Asphalt und Kaltasphalt hinsichtlich des Klimawandels an Bedeutung. Unter Recycling Asphalt oder Ausbauasphalt ist Fräsmaterial zu verstehen, welches aus einer Straße entnommen wird und nach Prüfung in einer anderen Straße wieder einzusetzen ist. Bei diesem Vorgang ist zwingend eine Bindemittelgehaltsuntersuchung (Bitumenprüfung) durchzuführen. Ebenso finden Asphaltprüfungen bei Neuentwicklungen oder der Forschung Anwendung. Diesbezüglich ist der Kaltasphalt in Deutschland noch nicht in den branchenspezifischen Regelwerken (ZTV Asphalt-StB 07, TL Asphalt-StB und TP Asphalt-StB) etabliert. Um diesen flächendeckend ein zu führen, müssen zuvor umfangreiche Studien stattfinden.

Welche Prüfverfahren und Untersuchungsaspekte gibt es für den Baustoff Asphalt?

- Asphaltanalyse/Bindemittelgehaltsbestimmung: Zerlegung des Asphalts in seine Komponenten Mineralstoff/Gestein, Füller, Bitumen und ggf. andere Zusätze

- Verdichtbarkeit: Für die Bestimmung des Hohlraumgehalts, des Verdichtungswiderstands oder der Raumdichte sind zunächst normgerechte Probekörper herzustellen

- Temperaturverhalten: Untersuchung der Eigenschaften von Kältereaktionsverhalten, Steifigkeit, Ermüdungswiderstand oder Dehnungsverhaltens bei dynamischen Temperaturen

- Verformungswiderstand