Extraktionsautomat EA 218 für nicht brennbare Lösungsmittel, nach DIN 1996 T.6 und EN 12697-1

• Einfache und übersichtliche Bedienoberfläche mit Touchscreen

• Indirekt beheizte Auswascheinrichtung für Siebtrommel mit einer

Probemengen bis 3,5 kg

• Effektives Waschsystem durch vollständige Lösugsmitteltränkung der Probe

• Schonende Behandlung der Probe zur Verhinderung von Abrieb

• Zentrifuge mit optimierter Spindeldrehzahl

• Entnahme der Bitumenvorprobe mittels Kugelhahn aus der Rückgewinnung

nach Ende des ersten Waschgangs jederzeit möglich

• Einsetzen und Entnehmen der Schleuderhülse mit Einhandausziehhilfe

• Rückgewinnungseinheit mit indirekter Heizung für eine

schonende Bitumeneinengung und Lösungsmittelrückgewinnung

• Sichtfenster in der Rückgewinnung für eine bessere visuelle

Überwachung der Rückgewinnungsprozesses

• Microprozessor gesteuerte Fehlerüberwachung

mit farbiger Statusanzeige zur schnellen visuellen Kontrolle des Betrieszustandes

• Dosieranschluss für Stabilisator

• Wasserfeinfilter am Wassereingang

• Wasseranschluss mit Schnellkupplungen für Schlauch ½“

• Verwendbar für verschiedene nicht brennbare Lösungsmittel

Werksseitig eingestellt auf Perchlorethylen

Abmessung (BxTxH): 1200 x 800 x 1500 mm

Anschluss: 230/400 V, 50 Hz (1=L1, 2=L2, 3=L3, 4=N (0), PE )

Absicherung: 3×16 A Leistung: 3,5 kW Gewicht: 350 kg

benötigte Kühlleistung 3 kW

Lieferumfang:

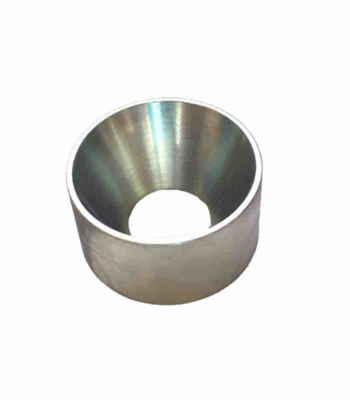

2 Schleuderhülsen 1.007

1 Ausziehvorrichtung für Schleuderhülse

1 Siebtrommel 1.019

1 Siebpinsel aus Messing 7.422

1 Auffangschale 120 mm aus Glas

*Der Extraktor darf nur in einem dafür vorgesehenen Abzugschrank betrieben werden*

-Passender Kühlwasserrückkühler: 1.047.10

*****Gesamte Merkmale siehe Produktinfo****